Company

Information relating to the company ConformTech

-

Our profile

After 18 years in the business, Les Consultants ConformTech has built a solid reputation in the steel industry. We are particularly proud of being pioneers in the understanding of bolt tensioning.

The company relies on a small team of professional experts, trained and qualified technicians and engineers with over 25 years of experience.

Over the years, we have consolidated our clients trust for being their inspection company for their big engineering projects and those of smaller proportions.

We specialize in quality control in non-destructive testing, welding and endoscopy with several reputed clients whose respectability supports the credibility of our expertise.

Currently, we are developing a recognized training program for the quality control portion of the manufacturing and installation of structural steel for buildings.

-

-

-

-

-

Our values

Integrity of Les Consultants ConformTech and its team has always dictated the guide lines for their services.

As a team, we work together and in close collaboration so that the experience and expertise of each can ensure the best performance for our clients.

We ensure a transparency in our services for our clients.

Availability, speed and flexibility of our services contribute in guaranteeing that the information is well transmitted.

Our rigorous inspection ensures a finality that is in respect to the project’s design.

Our culture

We perform for our clients with complete professional services because we believe that our client is the guarantor of our success.

Our approach is simple: Understand and logically interpret the applicable standards so that the quality of the product reflects what has been designed in order to guarantee the safety and durability of the structure.

Our complete and descriptive reports are based directly on the clauses of the relevant standards and suggest corrective measures and solutions.

The loyalty of our clients is a core value of Les Consultants ConformTech and it is earned by complying with the expected quality standards.

Projects

A few achievements

Our Services

Quality Control / Surveillance / Inspection / Welding / Non-destructive Testing

NOTE: We specialize with all grades of steel.

Fabrication in steel shops

- - Verification of Personnel qualification / certification of the company / Welding procedures according to W47.1-09 standard.

- - Verification of welding procedures according to W47.1-09 standard.

- - Verification of chemical compounds and mechanical tests results in the mill test certificates as defined in the tables of the CSA G40.20 /21 code and verification of the welding rods according to the CSA W48.1 code.

- - Evaluation of the welding process with the equipment’s used in accordance with the approved welding procedures.

- - Dimensional verification of the pieces according to the acceptance criteria’s of the CSA G40.20 standard.

- Vérification de l’ajustement des joints soudés selon les dessins et les exigences de la norme CSA W59-F13.

- - Verification of the adjustment of the welded joints according to the drawings and the requirements of the CSA W59-F13 code.

- - Non-destructive testing (magnetic particle, liquid penetrant, ultrasound) according to the CGSB requirements.

- - Verification of painted, metalized and galvanised coatings according to the CPMA 1-73a, CPMA 2-75, SSPC-NACE, CSA G189 and CSA G164 standards.

On field erection

- - Verification of anchors according to the CSA A23.3, CSA S16-09 and technical information supplied by the manufacturer.

- - Verification of erection tolerances according to the CSA S16-09.

- - Verification of welded joints according to the CSA W59-F13.

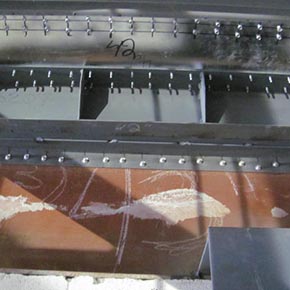

- - Verification of firm contact bolted joints or pretension bolted joints according to the function of the assembly as described in the CSA S16-09 and the seismic category of the structure.

- - Verification of crane runways according to B167 standard and the CISC guide.

- - Verification of the steel deck installation (sheets, nails, screws, studs and shear collectors) according to the technical specifications of the manufacturers like CANAM or Hilti and the requirements of the CSA W59-F13 standards, respectively.

- - Verification of paint touch-ups.

- - Preparation of the preliminary stage (bolting procedures and procedural meeting with the client) as required by the CCDG.

- - Follow-up of the stages in the bolting process according to the CCDG and the CSA S6-06 standard.

- • Reception and storage of the bolts

- • Tension testing of bolts with the "skidmore"

- • Verification of the contact surface preparation

- • Installation of temporary and permanent bolts

- • Verification of the snug tight condition of the assembly

- • Verification of the tensioning process using the turn of nut method.

- • Final approval of the assembly

- - Weld examination of the bridge bearings according to Chapter 12 of the W59-F13 standard.

We visually examine the structural condition and, if necessary, load the device. We examine welds susceptible to cracking with Magnetic particle testing and examine pins and shafts with dye penetrant or ultrasound testing in articulated joints.

- - Cranes according to CSA Z150s

- - Platform lifts according to standard B354

- - Articulated booms according to standard B354

- - Amusement park rides in accordance with Chapter 12 of the W59-F13 standard

- - Quality control for structural steel buildings

- - Bolting of Highway Bridges

- - Corrosion Types

- - Causes

- - Remaining steel thickness

- - Recommendations for surface preparation type and protective coating type.

Contact us today for a quote

1-450-539-0482